Technical Services

Download center

Tel: 020-87201881

E-mail: admin@udgroup.com.cn

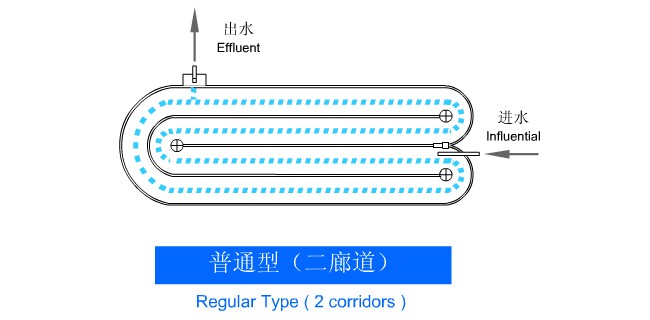

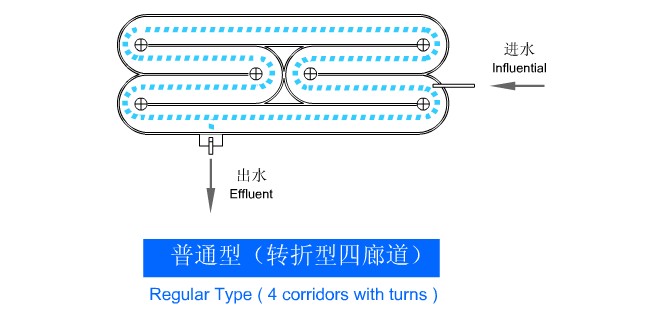

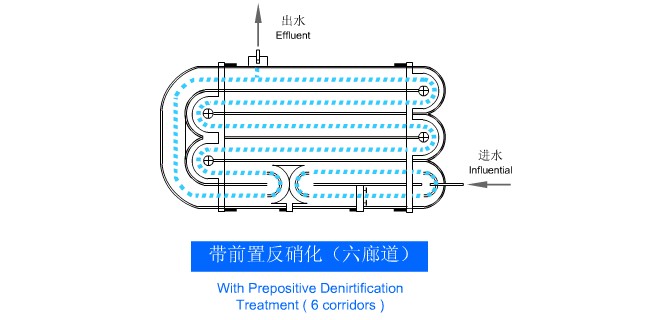

Oxidation Ditch Process

In the domain of oxidation ditch process, U&D undertakes two projects of national 863 program, i.e. “A Study on Complete Equipment of Urban Sewage Oxidation Ditch Treatment Process” (no. 2004AA601060) and “Development and Application of Highly Efficient Complete Aerator for Sewage Treatment” (no. 2009AA063804). On the basis of the existing oxidation ditch technologies at home and abroad, and through the systematic studies on the process, U&D launched the “GZ2007 Oxidation Ditch” process, and, while applying for the patent, it succeeded in applying the process to the demonstration projects, so further consolidating the leading position of U&D oxidation ditch process in the industry.

Based on the long tracing and analysis of the actual running conditions of the traditional surface aeration type oxidation ditch process in the similar sewage treatment plants of the company, U&D keeps adjusting and optimizing the design parameters of all parts, makes its every effort to reduce the engineering investment and running costs, and also provides technical support relating to oxidation ditch process for many national and provincial design institutes.

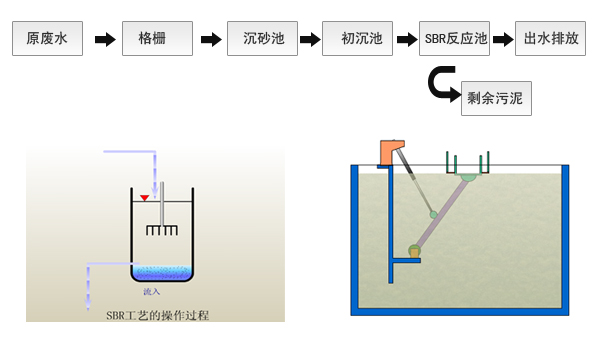

SBR Process

The real-time control technology of SBR process does well in organic removal, denitrogenation and dephosphorization, as well as in high strength ammonia wastewater denitrogenation. At present, the complete equipment of SBR sewage treatment process and real-time control technology have been applied to more than sewage treatment projects distributed in the Yellow River basin, Liaohe River basin, Songhua River basin and the like, which save the engineering investment by 10-15% on average, and also reduce the running costs by 15% or so.

Now the technology has been widely applied in the engineering design.

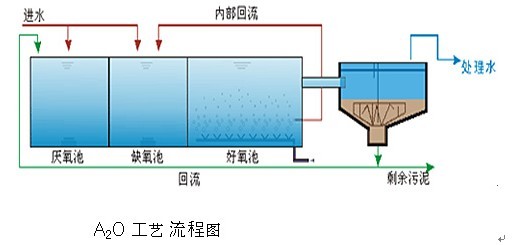

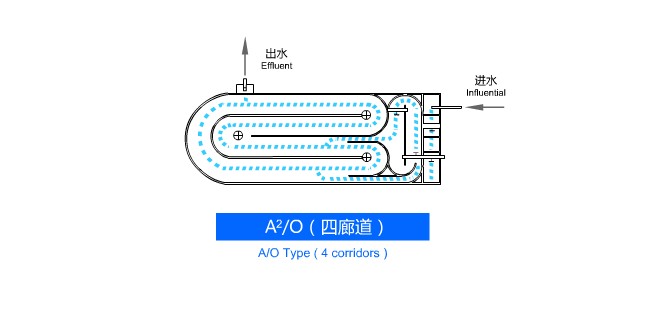

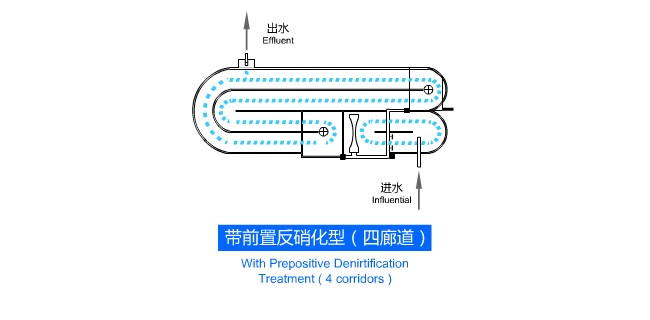

A2/O Process

A/A/O process refers to the anaerobic / anoxic / oxic activated sludge process. In its structure, the anoxic zone is added behind the anaerobic zone and before the oxic zone. The oxic zone has the nitration function, and allows the mixture in it to flow back to the anoxic zone for denitrification, to be denitrogenated. While the sewage is flowing through these three functional zones, the organics, nitrogen and phosphor are removed by the various bacterial populations, and the purpose of biological dephosphorization and biological denitrification is thus achieved.