Home > Service Items > Products > Sewerage > Screen

Related Product recommendation

Tel: 020-87201881

E-mail: admin@udgroup.com.cn

I. Product Overview

The drum screen (also called helical pressing screen or helical fine screen) is used for the preliminary sewage

treatment process. It can be applied for urban sewage, industrial wastewater and domestic wastewater

treatment projects, and intercept floats in water, and

it integrates pollutant interception, helical lifting and dirt pressing. It is now a relatively advanced fine screen.

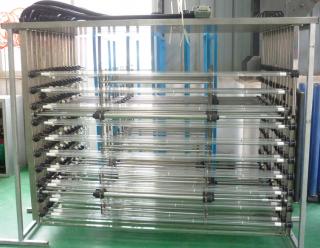

The drum screen consists of rotary screening drum, screening drum roller, front and rear stiffening rings and

dirt trap, conveying presser, bracket, drive unit, washing device, etc.

II. Technical Features

The device integrates cleaning, conveying and pressing well, increasing energy utilization while reducing investment

in management. With fixed space between screening drums, it can provide thorough cleaning, with the

decontamination efficiency of over 98%, and so it does not have such defects as exist in the ordinary harrow

type screen owing to variable space between screens. The ends of the screening drum are fixed by welding onto

the screening drum through thickened stainless steel rings that are precisely cut and have excellent concentricity, to

ensure the drum’s concentricity during its rotation. The rotational power of the helix of the conveying pressing

device comes from the same reducer as that of the screening drum. The helix of the conveying pressing device

is a pivoted one, and its blade is made of stainless steel. The pitch decreases gradually from bottom to top, but

the pressing capability increases by degrees.