- Product Overview

- Comments

- Project Case

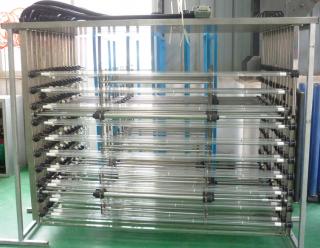

I. Product description

Combined filler grows out of soft filler and semi-soft filler and thus possesses the virtues of these two types of filler. Structurally, a plastic disc buckle is changed into

a double-loop plastic ring. The acetalized fiber or polyester yarn is pressed onto the loop to evenly distribute the fiber

bundle. The interior loop is a snow-shaped plastic branch that can not only hang membrane but also effectively cut

air bubbles, so that oxygenation capacity and utilization are improved. The result is that bio-membrane is fully exchanged and the organic substances in the water are treated in a highly efficient manner.

II. Product features

The combined filler is high in thermal performance, small in resistance, good in performance of distributing water

and air, easy to grow membrane, and able to cut bubbles.

III. Applications

Applied to sewage and waste water treatment projects, and such facilities as oxidation tower and oxidation groove in

oxidation tank, the combined filler is a bio-carrier for disposing waste water through bio contact oxidation method and

anaerobic fermentation method.