- Product Overview

- Comments

- Project Case

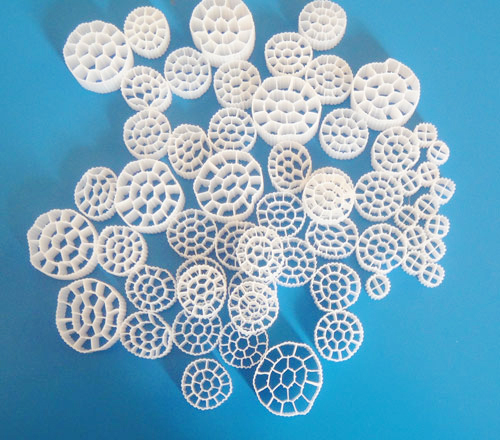

In MBBR process, fluidized bed filler is the reactor’s core part. The filler, if selected appropriately, can ensure

efficient operation of the reactor; however, the inappropriately selected filler may result in the failure of the whole

treatment process. The fluidized bed bio-affinity filler in general satisfies the requirements below:

(1) Superb hydraulic characteristics

The hydraulic characteristics of the filler include specific surface area, porosity, structural shape, etc. The filler surface

is the place where bio-membrane is formed and fixed. A larger specific surface area is the primary condition for the

reactor to keep high concentration of biomass, and is also the primary factor for affecting the result of treating sewage

with the bio-membrane method. In general, a large specific surface area is favorable for sewage treatment; however,

the greater the specific surface area is, the more easily the reactor will be clogged, and more resistance the water

flowing inside the filler will face. The greater the filler’s porosity is, the more efficiently the space will be utilized and

the smaller flow resistance will be. In this way, the possibility of reactor clogging and short circuiting will be reduced.

Besides, the reduced use of filler will reduce the whole capital outlays accordingly. The higher the porosity is, the

smaller the specific surface area and mechanical strength will be. The structural form of the filler affects not only

specific surface area and porosity, but also water flow between fillers, thus influencing the mass transfer between

waste water and bio-membrane and the renewal of bio-membrane. The shape of the filler also affects hydraulic characteristics. The filler shape shall be selected on the

principles: 1) good protection on the immobilized microorganisms;2) good mass transfer; 3) reduction in energy

consumption of the reactor.

(2) Mechanical strength

In most of biological processes exist hydraulic shearing forces of various strengths, as well as the friction and

collision between fillers. The shearing force appears more obvious in MBBR. Therefore the bio-membrane filler must have the mechanical strength that accommodates the applied biological technologies. If the

bio-membrane filler itself doesn’t possess some mechanical strength, then varying degrees of damage will

inevitably occur in the filler’s operation. This will lead to irregular changes in biomass held within bio-membrane reactor and ultimately produce the changes in the quality of the water discharged.

(3) Stability

The filler must be of so good biological, chemical and thermodynamic stabilities, that the filler itself will not experience

biochemical reactions within the system. The bio-membrane will generate various metabolites in metabolic process. Of these metabolites, some will corrode the filler.

In actual application, the filler should be inert to the extent that it will not experience the bio-chemical reactions of

bio-membrane. The filler itself is non-biodegradable. It will show the greatest inertia against chemical reactions and

corrode the environment. Meantime, the bio-membrane filler should generate inertia against the changes in surrounding temperatures and will not be subject

to any reactions and deformations when temperature varies.

(4) Adhesion of bio-membrane

The adhesion of bio-membrane onto the filler depends upon the physical and mechanical characteristics of the filler

surface.

The first characteristics are porosity and roughness of filler surface. The surface roughness will determine whether

the bio-membrane can be quickly developed. The rougher the surface is, the faster membrane hanging will be. The

surface porosity will also affect the bio-membrane’s adhesion. The small pores can be strong in retaining

microorganisms. Only when 70% of the pores

on the filler’s surface have the diameters 1-5 times the size of the greatest microorganism in the reactor, can the

greatest bioaccumulation be gained.

The second characteristics are filler’s surface static and water affinity. In the pH value, the microorganisms generally

take negative charges. If the carrier’s surface takes positive charges, it will be favorable for biological immobilization.

In accordance with the free energy minimization principle of physical chemistry, water-affinity microorganisms are

likely to adhere to water-affinity filler’s surface. However, hydrophobic filler is favorable to the immobilization of

hydrophobic microorganisms

on the surface. The water affinity and hydrophobicity of the filler surface may be completed by modifying the filler

surface or realized by directly processing the filler’s raw materials.

(5) Moderate specific gravity

The specific gravity of the filler and the water ratio approach 1.MBBR technology requires the filler with bio-membrane to flow with water under the aerated conditions; therefore the specific gravity of the filler is required to

be close to the water ratio.