- Product Overview

- Comments

- Project Case

I. Product Overview

U&D biological filtration and purification system is an economical and applicable biological filtration and

deordorization technology developed for domestic sewage deordorization, based on deordorization technologies

at home and abroad as well as actual running conditions.

II. Working Principle

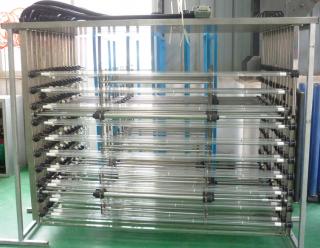

The biological filtration and purification system is mainly composed of the high-efficiency composite biofilter, filler making for biological adhesion and growth adhesion and high-efficiency composite microbiological strain. In the composite biofilter, the microorganisms are allowed to live in a

suitable environment, and form the biomembrane on the organic biological filler surface. The microorganisms in

the biomembrane use the minerals and

organics in waste gas as carbon source and energy source, maintain their lives by degrading the malodorous

substances, and decompose such substances into odorless substances like water, carbon oxide and mineral matter.

Biological purification of malodorous gas refers to a process in which the microbiological strains are used to

decompose and oxidize malodorous gas into CO2, H2O and other harmless and odorless gases that are then

discharged. In terms of nature of biological filler and structure of treatment equipment, the biofilter is usually divided

into three categories, i.e. biological land deordorization filter, biological composting deordorization filter and biological

deordorization filter. The biofilter-based deodorization technology is a relatively new biological deodorization technology

that emerged in the last years.

Its main principle is placing or inoculating biological strains on inert filler, called bio-film formation; when waste gas enters the inert biological filler on which biological strains have been inoculated (matured), some flows into the liquid phase, while some comes into the microbiological membrane on the inert filler

surface and is captured, absorbed and decomposed by microorganisms in it.

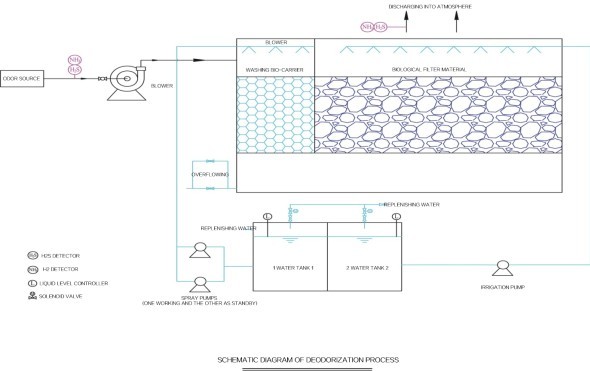

II. Process Flow

The collection device on the tube supplies malodorous gas to the humidification and washing device of U&D system.

The humidification and washing device uses the high-pressure atomizing nozzle to atomize water, and then the atomized water mixes with gas flow to be treated, which

reaches the saturation state quickly, thus creating good conditions for stable running of the biological filtration process.

The humidified waste gas flows into the U&D biofilter from bottom to top through the gas distributor, and at the same

time, the microbial nutrient solution is evenly distributed on the filler layer after atomized on the top of the biofilter, and

then comes onto the filler surface from top to bottom. While moving from bottom to top, waste gas flows through the

filler layer and comes into full contact with the biological membrane formed on the filler surface, and is then oxidized

and decomposed by microorganisms into CO2, H2O, inorganic salt, mineral, etc, to achieve the purpose of

deodorization.

IV. Technical Features

※ The device uses the normal, rational and standard engineering design, reducing energy consumption, lowering

running cost, and making the most of resources.

※ The device is of multi-unit and multi-modular optimal combination structure, and has a multi-point air inlet.

※ The biofilter is of box structure as a whole, and the water pump, water tube, meter and control cabinet are all

installed on the device to form a whole with the device.

※ The device is of bi-layer structure. The outer layer can be used for long in the environment full of malodorous gas;

the middle layer is an insulation layer that can be used in winter; and the inner layer is an anti-corrosive layer.

※ The reverse flow technology is used, namely, waste gas flows from bottom to top of filler, while atomized water runs

from top to bottom and gather within the nutrient box.

※ The device can be made of PVC, FRP or stainless steel.

※ Under the filler layer a gas distributor is installed to ensure even distribution of gas.

※ Filler can be plant, plastic or pottery.

※ Inert filler biofilm can be in long-time use, and needs not to be replaced.

※ The special filler has large surface area but small voidage, ensuring small wind resistance and low energy

consumption of the whole device.