- Product Overview

- Comments

- Project Case

I. Product Overview

The design of the entire structure of the pump is bold and innovative. Independent bearing body and support are

used to solve the problem of supporting the vertical pump with motor bearing; the impeller developed based on

excellent hydraulic model is used to solve the problem of big axial force of vertical pump; Y series standard general-purpose motor is used to make it convenient for the user to replace the long motor shaft of the vertical pump; and

the completely easy-to-remove structure will facilitate the replacement of bearing, mechanical seal, impeller, pump

spindle of high-power pump.

Compared with similar domestic products, this pump has such irreplaceable advantages as steadier running,

longer service life, more convenient replacement, easier maintenance, etc. Among vertical pumps, this product

has advanced technology and is the most ideal substitute for ISG type vertical pump, IS typecentrifugal pump,

S type double entry pump, etc.

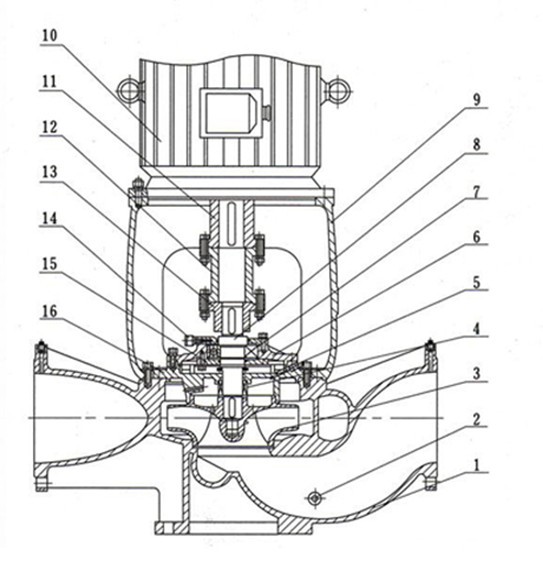

1.Pump body, 2 drain plug, 3 impeller, 4 mechanical seal, 5 deflation valve, 6 bearing body, 7 bearing,

8 pump spindle, 9 support, 10 motor, 11 motor coupling, 12 intermediate coupling, 13 pump coupling,

14 oil cup, 15 bearing gland, 16 pump cover

Pump body: The spiral type pump body is designed and manufactured based on optimal modern hydraulic model.

Its flange

is consistent with the standard of GB4216.5, with Rp1/4 or Rp1/8f pressure measuring pipe.

Impeller: It is made of closed-type cast iron. The excellent hydraulic model and special structure ensures the

efficiency of the pump and can

reliably eliminate the axial force.

Mechanical seal: maintenance free at a water temperature of below 150℃, without rotation limitation. The special

design can ensure the compensatory and sealing performance of the rotating ring.

Pump spindle: The optimal design integrates pump spindle and coupling, which reduces the size of the drive

shaft and that of the pump, so that the pump can operate in a safer and more reliable way.

Pump bearing: NTN or NSK precision bearing is used, with low noise and long lifetime.

Motor: Y or Y2 series squirrel cage AC motor, BS type. Standard general-purpose motor is used to facilitate

maintenance, and high-power pump is equipped with lubrication hole for maintenance of bearing.

II. Technical Features

1. The vertical structure is convenient for installation and debugging; the specially designed motor and pump body

are connected by coupling, with high concentricity and machining precision, and less floor space helps to reduce

30%-60% of the cost of pump room. The stable seat, compact structure, and elegant casting and appearance

make the vertical type centrifugal pump full of artistic charm.

2. Y series standard general-purpose motor from a well-know manufacturer is used to ensure stable and

low-noise running.

3. Famous-brand precision bearing is used, with high precision, good reliability and long lifetime.

4. Excellent self-balancing axial force hydraulic model is adopted for impeller, greatly prolonging the lifetime of

pump bearing and mechanical seal.

5. The bearing inside the motor bearing seat is equipped with oil filling hole and drain hole, which is convenient

for maintenance.

5. The removable hard intermediate coupling eliminates vibration and noise during pump starting. The rotating

components have reliable safety protection cover.

7. The mechanical seal made from stainless steel, tungsten carbide and fluorine rubber can withstand high

temperature and pressure, has long running lifetime, without leakage and shaft abrasion, which can ensure

a clean working environment.

8. The pump cover is specially designed. The bearing seat can be taken out conveniently by removing the hard

intermediate coupling and pump cover nut. For such assembled components as pump cover, pump spindle,

impeller, etc., mechanical seal and impeller need to be replaced, and disassembly of the motor, pump body

and pipes is not necessary, thus maintenance is convenient and rapid.

III. Application

The product has a wide scope of application. It can be used to transmit different media including water or

industrial fluid, and can be applied at different temperature, flow and pressure.

The typical applications include:

Water supply: Water works filtering, transmission and separate water supply, and pressure boost of main pipe

Industrial pressure boost: process water system, cleaning system

Industrial fluid transmission: boiler water supply, condensation system, cooling and air-conditioning system,

machine tool, acid/alkali transmission;

Water treatment: distillation system or separator, swimming pool, etc.

Farm irrigation, petrochemical industry, medicine and sanitation, etc.