- Product Overview

- Comments

- Project Case

Ⅰ.Product Overview

Sludge dryer dry the sludge by heating power, the dried sludge is in pellet or powder, whose diameter is below 5mm. The dryer has a efficient heat sterilization as the activity of microorganism, whose water content is below 10%, is suppressed to prevent the sludge from being smelly. After drying, sludge contains 1400~1700 calories so that abundant creature and fiber in it could be used as fuel to kill the pathogens completed and decompose the poisoned organic remains. Finally, the reutilization of remains and cinders could prevent sludge landfill or other treatment ways from bringing secondary pollution.

Ⅱ.Process flow

1. Feeding: Dewatered sludge with a water rate of 80%-86% is convoyed to dryer's feeding inlet by screw or belt convoyor.

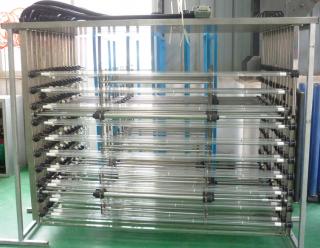

2. Heating: To use steam or heat transfer oil as heat source, heat carrier(steam or heat transfer oil), whose temperature is 120~230℃, will be flowed into the shell and screw and blade desperately to contact sludge.

3. Sludge drying: Heated metal cover contact the sludge uniformly to heat and evaporate sludge, and along the shaft of dryer, steam evaporation desperate into two phases: constant evaporation rate and low evaporation rate.

4. Waste steam treatment: Stream treatment applies spray tower and active oxygen waste gas purification equipment to make the exhausted steam achieve the effect of dust removing and deodorization and be qualified for the discharge standard.Ⅲ.Technical advantages

1、Quick drying, small site area and pollution

2、Dryer has large heat transfer area so as to shorten the treatment time

3、wide application scope4、little pollution

5、Stable operation, low maintenance fee

6、Easy operation

7、Effective sterilization, meet environmental standard.

Ⅳ.Equipment selection

Ⅴ.Technical Parameters

1、Water content before dryer is up to 80~90%.

2、Water content after dryer is 15~35%

3、Sludge volume variation: reduce by 4-5 times

4、Capacity: 1~60 Ton sludge with a water content up to 80% per day, after drying, every ton sludge can convert to 0.15~0.35 ton powder and dried sludge powder with a diameter of 5mm.Inferior calorific value for dried sludge powder is about 1300~1500 calorie.

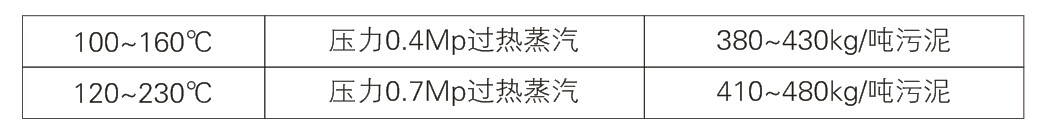

5、Steam consumption amount

6、Cost calculation: The cost of steam is 180 RMB per ton, so the cost of drying one ton sludge is calculated as below:400 kg x 0.18 RMB/kg = 72 RMB;The cost should be double (about 150 RMB) if adopt electric heating.The cost increases twice for secondary energy conversion. Thus, the cost rises much.

7、Heating supply: steam and heat transfer oil.

Ⅵ.Application

Application in organic and inorganic sludge drying for such industry as printing and dyeing, thermoelectricity,

paper making, leather, printed circuit board,Ⅶ.Economical value of dried sludge

1.Sludge burning: After drying, the heat value of sludge is about 1300 to 1500 calories, three tons of dried sludge is equivalent to one ton of coal with 4500 kcal, dried sludge can be adopted to boiler combustion with a mixture of coal, one ton of dried sludge can produce one ton of steam.

2.Brick making: Dried sludge, can be added in clay to make brick with the mass ratio of 1:10, whose intensity is equivalent to ordinary brick, and has a certain amount of heat. In the process of brick making, dried sludge can be burned spontaneously to increase the heat.

3.Biochemical fibreboard making: Under basic conditions, there are a series of chemical changes to the dried sludge after heating, drying, pressing (protein denaturation). With this kind of denaturation, sludge will convert to activated sludge resin (protein gel) to make its fiber bonding and finally make fibreboard.

4.Cement admixture

5.Landfill & Composting: Dried sludge can be used for composting because the organic sludge containing nitrogen, phosphorus and potassium is a necessary fertilizer for the crops during the growth. Organic ingredients crude protein or globulin in activated sludge is a good soil conditioner, the sludge can be used as fertilizer with a value of agriculture because of its stable nature.

6.Landscaping: After drying, sludge still keeps more effective organic matter and nutrients. On the premise that heavy metals and other hazardous substances meet the relevant requirements of the standard, dried sludge can be applied to landscaping, composting for urban nursery base as well as soil improvement of wasteland and hillsides around the city, fast-growing forest, fruit trees planting.